Don’t throw away your old shoes before you get new ones – that’s an adage the Dutch sweet pepper grower Stephan Persoon firmly believes in. Now he and his cultivation manager Roel Klapwijk are putting out feelers in the direction of Next Generation Growing, and instead of replacing the old screen fabric they decided to install a second climate screen under it. It took a while to work out how best to install it.

The first green peppers have been harvested at Personal Vision in Bleiswijk. The new season is just around the corner and changes are in the pipeline in Stephan and Thea Persoon’s 7 hectare nursery with their son Roy having recently joined the team. They grow three main varieties of red peppers and they are also trialling several new varieties from various breeders. This broad palette is a good reflection of how the company works. At Persoon they manage their own sales without the intervention of a growers’ association. Every customer has their own preferences and with several different varieties in house, Persoon can meet all their requirements.

Crop manager Roel Klapwijk has been part of the team for ten years now and specialises in climate control. He attended one of the Next Generation Growing (NGG) courses and came away with several new ideas. Like many sweet pepper growers, Persoon listened to what was being said and let it all sink in for a while. “I built up my whole cultivation strategy around my own experience and intuition. It’s hard to just let that go. I can see that the younger generation doesn’t carry this ‘baggage’ around with them!” he says.

Second screen

Nonetheless, he is open to change and therefore to NGG as well. So last year Klapwijk started to experiment a little with their existing energy screen, above a variety that happily stays generative. He allowed the temperature to rise slightly higher there, except on the hottest nights.

Last winter the time had come to make some changes to the screen system, which plays such an important role in the new cultivation strategy. “We were planning to replace the old fabric”, Persoon explains. “But then we began to question whether that was such a good idea.” In their ten-year-old greenhouse with a six metre post height they have a Luxous 1243 D screen, says Ton Habraken from Svensson. It was actually working well in combination with a fixed AC foil at the start of production. Although it had seen a lot of use, it was not particularly worn and was technically still in a reasonable condition.

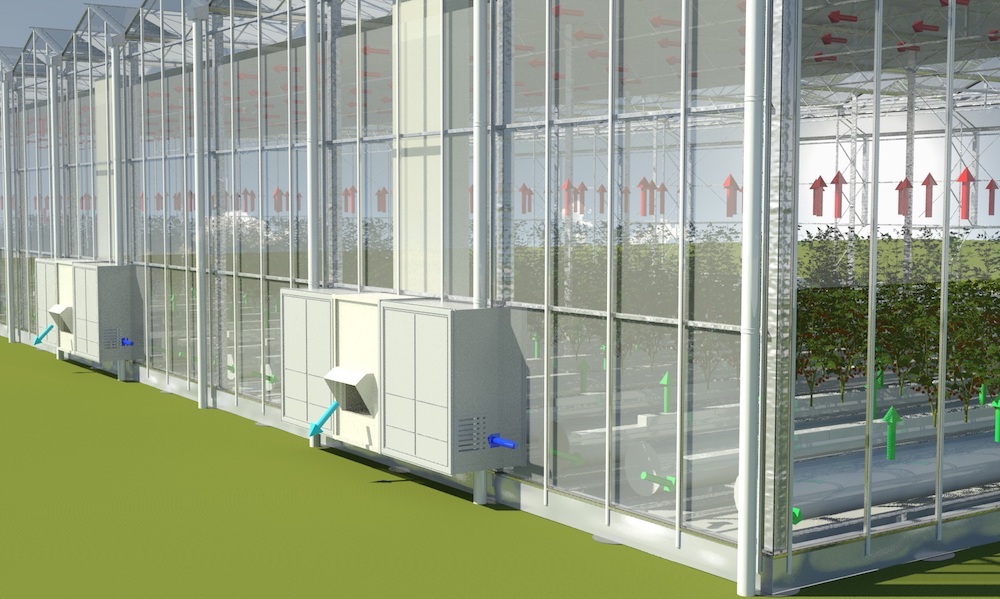

After the NGG course, it began to dawn on Klapwijk: why not add a second screen? It didn’t take them long to decide. Persoon: “We took the plunge and decided to leave the old diffuse screen in place and install a second screen, a clear energy Luxous 1347 H2no FR, underneath.”

Halfway up the trellis

That decision was not the end of it, however. The big question was where the second screen would go. The original wire bed is on top of the 12.8 m wide, 58 cm high trellis girder. Placing the second screen at the bottom would leave a gap of exactly the same width as the one above the first screen, allowing plenty of room for air movement.

“With the single screen, AC foil and horizontal fans we already get too many temperature differences. That’s what we want to avoid,” Persoon explains. He was already trialling moving fans around to better control air distribution in the greenhouse. He also fitted 150 sensors to measure the temperature distribution in the greenhouse.

Working with his regular fitters Steetec, he came up with a system in which the second screen would be installed halfway up the trellis, reducing the distance between the two screens to just 25 cm. The screens now close towards each other. Some modifications were needed to the drive shaft, the reverse wheels on the pull wires and the cross braces in the greenhouse. To reduce draughts above the screen, four vertical partitions were fitted along each bay in the 211 metre wide greenhouse. The growers hope that these measures will at the very least make things “calmer”.

Radiation meter

They also installed additional measuring equipment. There are now two sensor units measuring the temperature and RH above the screens. This enables Klapwijk to keep track of exactly what happens when the screens are closed. An RH meter and a radiation meter that records outgoing radiation into the sky were fitted on the weather station.

The screen can be closed on clear nights with high outgoing radiation, although that isn’t always necessary when there is cloud cover. The time of year is irrelevant: “Clear nights in summer sometimes produce more outgoing radiation than in winter,” Habraken explains. “On the other hand, in cloudy conditions there is sometimes very little difference between incoming and outgoing radiation. In that case, it’s often better to keep the screen open.”

Thermal imaging camera

The nursery has been using an infrared plant temperature sensor ever since it started out in 2006. A thermal imaging camera has now been added which measures the vertical temperature distribution in the crop. Klapwijk: “We know there are differences, but now I can really see what’s going on.” He doesn’t yet use the information from the camera to steer the crop because he wants to wait a while to see what happens in the crop first. “I expect to start using this information as a steering tool later in the season.”

Ultimately the cultivation manager will be able to decide what action to take based on measurements taken in the canopy and at the head of the crop. He will also be able to ascertain whether the temperature of the flowers or fruits is dropping below the dew point. The LetsGrow climate monitor tells him what is going on in real-time.

New climate regime

Last year the growers decided to apply a diffuse coating to some of the glass. Klapwijk: “The crop has become slightly more vegetative under the coating.” With this experience in the back of their minds, they will soon be applying a diffuse coating to the whole greenhouse to allow the light to penetrate further into the crop. The next step is to gradually implement a new climate regime. “We are already closing the screen at the end of the day more often, and we are making sure there isn’t too much vegetative growth.”

The question is whether the sweet pepper growers are ready to try growing at a higher temperature, as advocated in NGG. According to Persoon, that decision depends on the plant balance. If the plant load is too high, he doesn’t think they will. Or perhaps the higher temperature might actually help the fruits ripen more quickly. All in all, it looks set to be an interesting pepper season.

Summary

Personal Vision in Bleiswijk in the south of the Netherlands installed a second screen with clear energy fabric in March. The old diffuse fabric in the existing system has not yet been replaced. With this combination, the sweet pepper growers want to gradually apply the principles of Next Generation Growing. By installing the second screen halfway up the trellis girder, they aim to reduce air movement between the screens and ultimately improve the temperature distribution in the greenhouse.

Text and images: Pieternel van Velden.